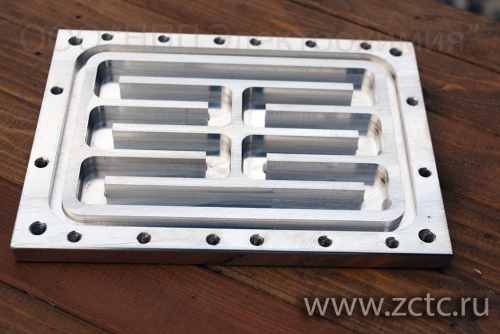

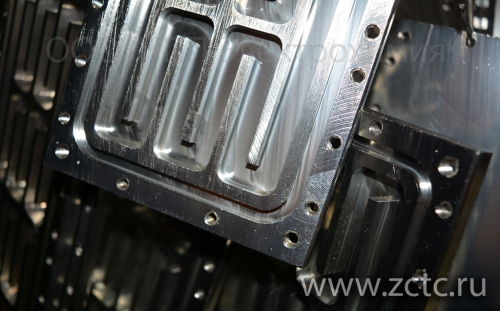

TINNING OF ALUMINUM WITH TIN-BISMUT ALLOY. BRILLIANT

Description

Tin-bismuth coating with a bismuth content of 0.2% on aluminum is widely used in electrical engineering, mechanical engineering and instrument engineering. The main functional task of tin plating is anti-corrosion protection of products, including those that are exposed to organic acids. Tinning is used to cover contacts, current-carrying busbars and grounding busbars. Tin coating is used as a separating layer when aluminum comes into contact with copper to prevent contact corrosion.

Tin coating of aluminum is fundamentally different from, for example, copper coating. Aluminum is a metal that easily passivates in air. Passive film has an extremely negative effect on the adhesion strength of the coating to the base. High-quality adhesion requires special preparation of aluminum.

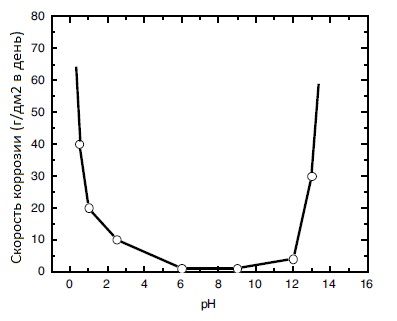

The corrosion rate of pure tin depending on the pH of the environment is shown in the figure:

You can order shiny tinning of aluminum with tin-bismuth alloy in accordance with GOST 9.305-84 by phone and email specified in the section "CONTACTS".

Characteristics

|

Designation (example) |

Sn-Bi |

|

Thickness |

3-100 microns (greater thickness is possible) |

|

Microhardness |

118-198 MPa |

|

Electrical resistivity at 18° C |

11.5⋅10-8 Ohm⋅m |

|

Permissible operating temperature |

200° C |

|

Bismuth content in Sn-Bi alloy |

0.2-2% |

Advantages of tin plating:

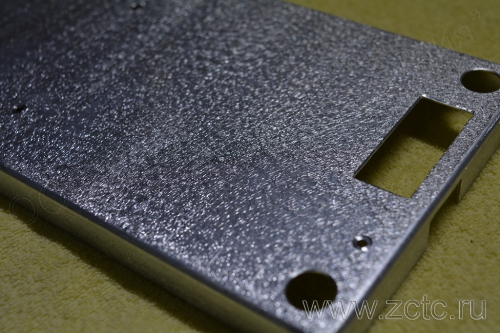

- Allows you to significantly increase the corrosion resistance of aluminum products. Shiny coatings, which, unlike matte ones, are less porous, are more durable. Porosity, in turn, affects the occurrence of interlayer corrosion along the zincate technological sublayer.

- Provides good solderability of aluminum. A shiny coating retains solderability for a longer time than a matte coating. Alloying with bismuth allows you to maintain solderability for longer than a year.

- Resistant to sulfur-containing compounds and recommended for parts in contact with all types of plastics and rubbers.

- Has good adhesion to the base metal and is well preserved during screwing.

- Brilliant tin coating is non-porous at layer thicknesses greater than 5 microns, while matte tin coating is characterized by significant porosity. The porosity of coatings down to 5 microns can be reduced by reflow.

- Doping with bismuth prevents the formation of conductive crystals ("needles") on the surface of the coating during storage, which is typical for unalloyed coatings.

- Alloying the coating with 0.5-2% bismuth allows you to avoid destruction of the coating at operating temperatures below -30°C. The destruction of tin coatings WITHOUT bismuth occurs due to the transition of compact white tin β-Sn into powdery gray tin α-Sn (“tin plague”).

Disadvantages of tin plating:

- Low wear resistance.

- Insufficient ductility compared to tin-lead and lead.

- Lower antifriction properties compared to tin-lead and lead.

- The presence of bismuth in the composition does not allow the coating to be used for food purposes.

Do you want to become our client?

Just leave your request by filling out the form on the right and we will contact you as soon as possible. Thank you!

By submitting an application, you agree to processing of your personal data. Your data is protected.